Exhaust System Performance Estimator

Select Your Components

Stock Manifold

Standard factory component

Headers

Aftermarket equal-length tubes

Standard

Emissions compliant

High-Flow

Better flow, emissions compliant

Standard

Stock muffler

Performance

Lower back pressure

Straight Pipe

Maximum flow, illegal in most areas

Performance Results

Notes: Results are estimates based on typical vehicle specifications. Actual performance may vary based on engine size, vehicle weight, and other factors. Always check local regulations before modifying exhaust systems.

In a car, exhaust system is a network of pipes, chambers, and sensors that collects combustion gases from the engine and directs them safely out of the vehicle while reducing noise and harmful emissions. If you’ve ever heard a rumble under the hood or noticed a faint smell of exhaust, that’s the system doing its job.

Why an Exhaust System Matters

The primary goals are three‑fold: move hot gases away from the engine, cut down the noise level, and treat the gases so they meet legal emission limits. Without it, the engine would overheat, occupants would be exposed to toxic fumes, and the car would fail inspections.

Key Components and Their Roles

Every part has a specific job. Below is a quick tour of the most common pieces.

- Exhaust manifold: Sits directly on the cylinder head, gathering exhaust from each cylinder and funnel‑shaping it into a single pipe. Made of cast iron or stainless steel, it endures temperatures up to 1,200 °C.

- Headers: An aftermarket version of the manifold with equal‑length tubes that improve scavenging. Equal length reduces back‑pressure by up to 15 % on V‑type engines.

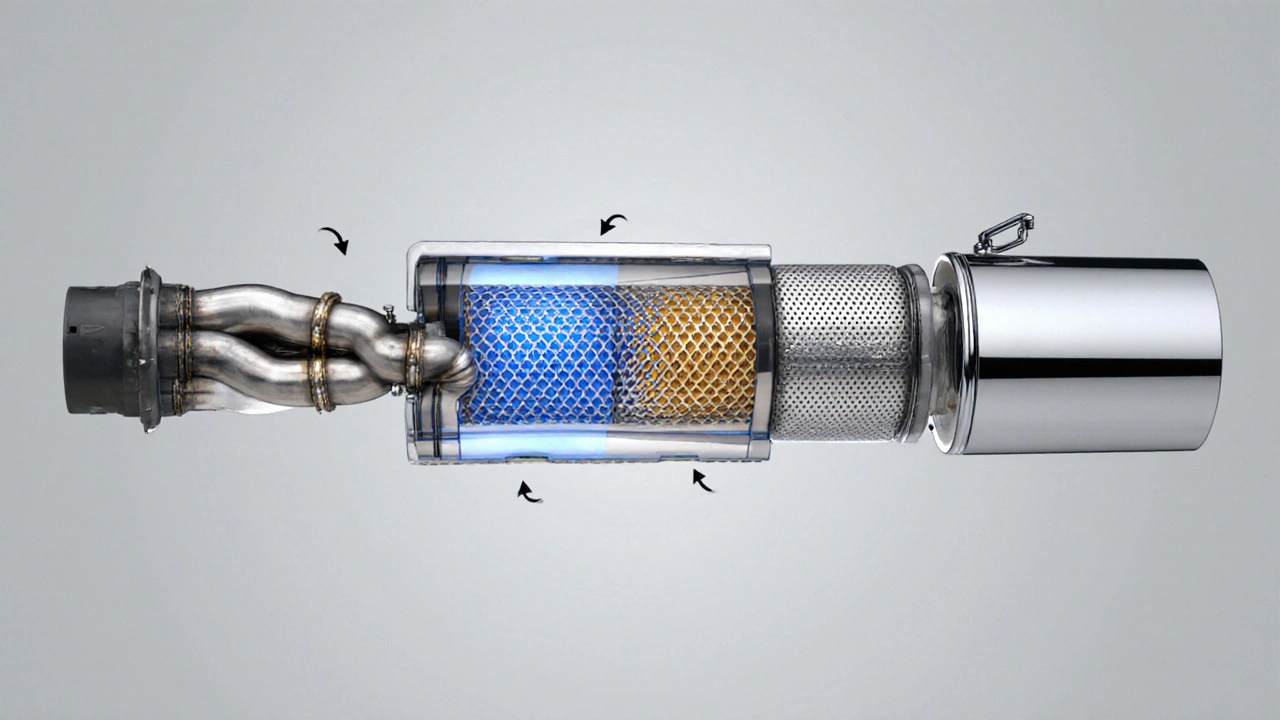

- Catalytic converter: The heart of emissions control. Inside, a ceramic honeycomb coated with platinum, palladium, and rhodium catalyzes reactions that turn carbon monoxide (CO) into carbon dioxide (CO₂), unburnt hydrocarbons (HC) into water (H₂O) and CO₂, and nitrogen oxides (NOx) into nitrogen (N₂) and O₂. It typically operates at 400-800 °C.

- Resonator: A chamber tuned to cancel out specific sound frequencies, smoothing the exhaust note without adding much back‑pressure.

- Muffler: Uses a series of perforated tubes and sound‑absorbing packing to reduce overall noise. A standard glass‑packed muffler can lower sound pressure level by 10-15 dB.

- Oxygen sensor: Monitors the oxygen level in the exhaust downstream of the catalytic converter. The engine control unit (ECU) adjusts the fuel‑air mixture based on its voltage signal (0.1-0.9 V for lean, 0.9-1.0 V for rich).

- Tailpipe: The final exposed pipe that directs treated gases away from the vehicle. Matte stainless steel or chrome is common; the diameter (usually 2-3 inches) influences flow and sound.

How the Exhaust System Works, Step by Step

- The engine fires, pushing burned gases into the exhaust manifold. This high‑pressure pulse begins the flow.

- From the manifold, gases travel through the headers (if equipped) or directly into the main pipe.

- The hot stream reaches the catalytic converter, where the catalyst speeds up chemical reactions that neutralize pollutants.

- After the converter, gases pass through the resonator and muffler. These chambers dampen sound waves, turning a loud roar into a more pleasant tone.

- The oxygen sensor measures exhaust composition, sending data back to the ECU for future fuel‑mix adjustments.

- Finally, gases exit the vehicle via the tailpipe, completing the cycle.

Because the exhaust is a high‑temperature, high‑velocity flow, each component must balance durability with flow efficiency. Too much restriction raises back‑pressure, hurting engine power and fuel economy.

Common Variations - Stock vs. Performance

Manufacturers ship a "stock" system that prioritizes low noise, durability, and compliance with emissions standards. Enthusiasts often swap parts for a "performance" setup:

- Cat‑back: Replaces everything from the catalytic converter to the tailpipe. Gains include a deeper sound and a 5-10 % increase in horsepower due to lower back‑pressure.

- Axle‑back: Swaps only the muffler and tailpipe. Cheaper, still improves tone.

- Straight‑pipe: Removes the muffler and resonator entirely. Delivers maximum flow but is illegal in most jurisdictions due to noise and emissions.

- Turbocharged exhaust: Requires larger‑diameter piping and a high‑flow catalytic converter to handle the increased exhaust volume.

When choosing upgrades, remember that each change can affect the ECU’s fuel mapping, especially if the oxygen sensor sees a different pressure profile.

Typical Problems and How to Spot Them

- Leaks: Hissing sounds near the manifold or muffler usually mean a crack or loose clamp. Leaks can cause a lean condition, leading to engine overheating.

- Rust and Corrosion: Salt‑laden roads accelerate rust on steel pipes. Look for brown flakes or holes, especially on the tailpipe.

- Clogged Catalytic Converter: A clogged converter creates excessive back‑pressure, triggering a check‑engine light (P0420 code). Expect a drop in fuel efficiency of 10-15 %.

- Failed Oxygen Sensor: Erratic voltage readings cause rough idle. Replacement cost averages $150‑$250.

- Excessive Noise: If the muffler is damaged, the sound level can jump by 8 dB or more, often accompanied by a rattling feel.

Regular visual inspections and occasional acoustic checks (listening for rattles) go a long way toward catching issues early.

Maintenance Tips and Performance Upgrades

Keeping the system happy is simple if you follow a few habits.

- Inspect the exhaust pipe and joints every 12 months for rust, cracks, or loose clamps.

- Use a high‑temperature stainless‑steel wire brush to clean the inside of the muffler if you hear a dull thud.

- Replace the oxygen sensor at the manufacturer’s interval (often 60,000 mi) to maintain optimal fuel control.

- When swapping a cat‑back kit, choose a high‑flow catalytic converter that meets your local emissions rules (e.g., Euro 6 or EPA Tier 3).

- If you add a turbocharger, upgrade the exhaust piping to at least 3‑inch diameter to prevent bottlenecks.

Performance‑oriented drivers sometimes install a twin‑pipe setup on V‑type engines, allowing each bank its own exhaust path. This reduces interference between exhaust pulses and can shave 2-3 % off the engine’s pumping losses.

Environmental Impact and Regulations

Modern exhaust systems are a direct response to legislation. The U.S. EPA’s Tier 3 standards (2023) and Europe’s Euro 6 limit carbon monoxide emissions to < 1 g/km. The catalytic converter is the main tool for hitting these numbers.

Future trends point toward even stricter limits and a shift to hybrid‑electric powertrains where the exhaust plays a secondary role. Still, many drivers will keep internal‑combustion engines for years, so a well‑maintained exhaust system remains essential for both performance and compliance.

Component Comparison

| Component | Primary Function | Typical Location | Common Material |

|---|---|---|---|

| Exhaust manifold | Collect gases from cylinders | Directly on engine head | Cast iron, stainless steel |

| Catalytic converter | Reduce pollutants via chemical reactions | Between manifold and muffler | Ceramic honeycomb with precious‑metal coating |

| Muffler | Absorb sound and lower noise level | Near rear of vehicle | Stainless steel, glass‑packed core |

| Resonator | Tune sound frequencies | Often before muffler | Stainless steel, perforated tubes |

| Tailpipe | Direct gases away from vehicle | Exterior rear end | Stainless steel, chrome‑plated |

Quick Checklist for Exhaust System Health

- Listen for hissing or rattling noises.

- Check for visible rust, holes, or loose clamps.

- Monitor check‑engine lights related to O₂ sensor or catalyst.

- Observe any drop in fuel economy or power.

- Schedule a professional inspection if you notice black smoke.

Frequently Asked Questions

What does a catalytic converter actually do?

It contains a ceramic honeycomb coated with platinum‑group metals that speed up chemical reactions, turning carbon monoxide, unburnt hydrocarbons, and nitrogen oxides into less harmful gases like carbon dioxide, water vapor, and nitrogen.

Can I replace my muffler with a straight‑pipe for more power?

A straight‑pipe removes flow restrictions, which can add a few horsepower, but it also creates excessive noise and will likely violate noise‑level regulations. It also eliminates the ability of the catalytic converter to stay hot, reducing its efficiency.

How often should I check my exhaust for leaks?

A visual inspection at least once a year is recommended, especially after harsh winters or if you’ve driven on salty roads. Pay attention to new hissing sounds or a change in engine idle.

Why does my check‑engine light flash after a catalytic converter failure?

When the converter clogs or melts, it raises back‑pressure, causing the oxygen sensor to report abnormal readings. The ECU then triggers the P0420 code and flashes the light to warn you of reduced performance and emissions.

Is stainless‑steel exhaust better than mild steel?

Stainless‑steel resists rust and can handle higher temperatures, making it a longer‑lasting choice, especially in salty or humid climates. It’s pricier, but the durability often outweighs the cost over the vehicle’s life.