Fuel Pump Symptom Checker

Select Your Symptoms

Diagnostic Steps

Analysis Results

Select symptoms and click "Analyze Symptoms" to get diagnostic feedback.

When your car starts acting up, you might blame the battery, the spark plugs, or even bad weather. Fuel pump is a mechanical device that delivers gasoline from the tank to the engine at the correct pressure. If it’s struggling, the whole power‑train feels the strain. Knowing the warning signs early can save you a roadside breakdown and a costly repair shop bill.

Key Takeaways

- Common symptoms include sputtering at idle, loss of power under load, and a whining noise from the tank.

- A simple pressure test or listening test can confirm a failing pump before you strip the car apart.

- Replace the pump when pressure drops below manufacturer specs, the motor whines loudly, or the pump leaks.

- DIY replacement is doable on most front‑engine cars, but a professional shop offers warranty and proper fueling system purge.

- Regular fuel‑filter changes and using quality fuel extend pump life.

Symptom Checklist: How Your Car Signals a Bad Fuel Pump

Below are the most reliable clues that your engine is being starved for fuel.

- Engine stumbles or stalls at idle - the pump can’t keep up when the throttle is barely open.

- Power loss during acceleration or uphill climbs - a drop in pressure means the injectors receive less gasoline.

- Hard start or no‑start after the car has been sitting - the pump may have seized.

- Clicking or whining sound from the fuel tank - the pump motor is grinding or its bearings are failing.

- Fuel smell inside the cabin - a leaking pump can vaporise gasoline into the cabin air.

- Check‑engine light (CEL) with codes P0230-P0234 (fuel‑pump performance) - an OBD‑II scanner will read these.

How to Test Your Fuel Pump Before You Replace It

Testing saves time and money. Two quick methods work for most cars.

1. Listen for the pump’s humming

- Turn the ignition to the ‘ON’ position without starting the engine.

- Stand near the rear of the vehicle and listen for a brief, steady whirring sound lasting 2-3 seconds.

- If the sound is faint, intermittent, or missing, the pump motor is suspect.

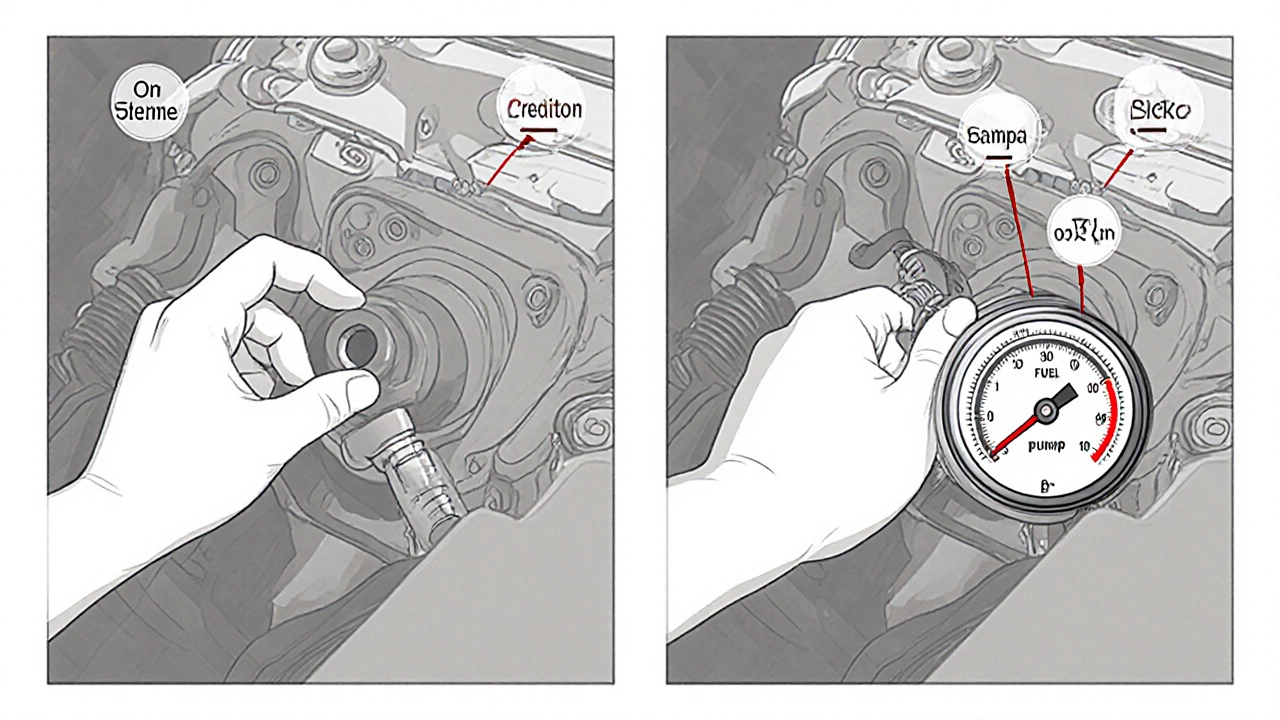

2. Measure fuel‑pressure with a gauge

- Locate the fuel‑pressure test port - usually on the fuel rail near the injectors.

- Connect a calibrated fuel‑pressure gauge.

- Start the engine and note the reading. Compare it to the specification in your service manual (typically 30-55psi for gasoline engines).

- Watch the pressure drop when the engine idles. A drop of more than 10psi indicates a weak pump.

If either test points to a problem, it’s time to consider replacement.

When to Replace vs. Repair

Fuel pumps are sealed units; they aren’t designed for component‑level repair. The decision boils down to three factors:

- Pressure loss beyond spec - a new pump restores flow.

- Visible leak from the pump housing - seal failure means a new unit.

- Motor noise that doesn’t disappear after cleaning - internal bearings are worn out.

Minor electrical glitches, such as a faulty fuel‑pump relay, can be repaired without swapping the pump. Use a multimeter to check voltage at the pump connector (12V constant when the key is on).

Cost, DIY, and Professional Options

In the UK, a replacement pump for a typical 1.5‑2.0L gasoline engine runs £80‑£180 for the part alone. Labour varies: a quick top‑up on a front‑wheel‑drive car may be £50‑£100, while a V‑engine under a body‑panel could hit £200.

If you’re comfortable with basic hand tools, a replace fuel pump DIY job looks like this:

- Relieve fuel‑system pressure (remove the fuel‑pump relay and run the engine until it stalls).

- Disconnect the battery.

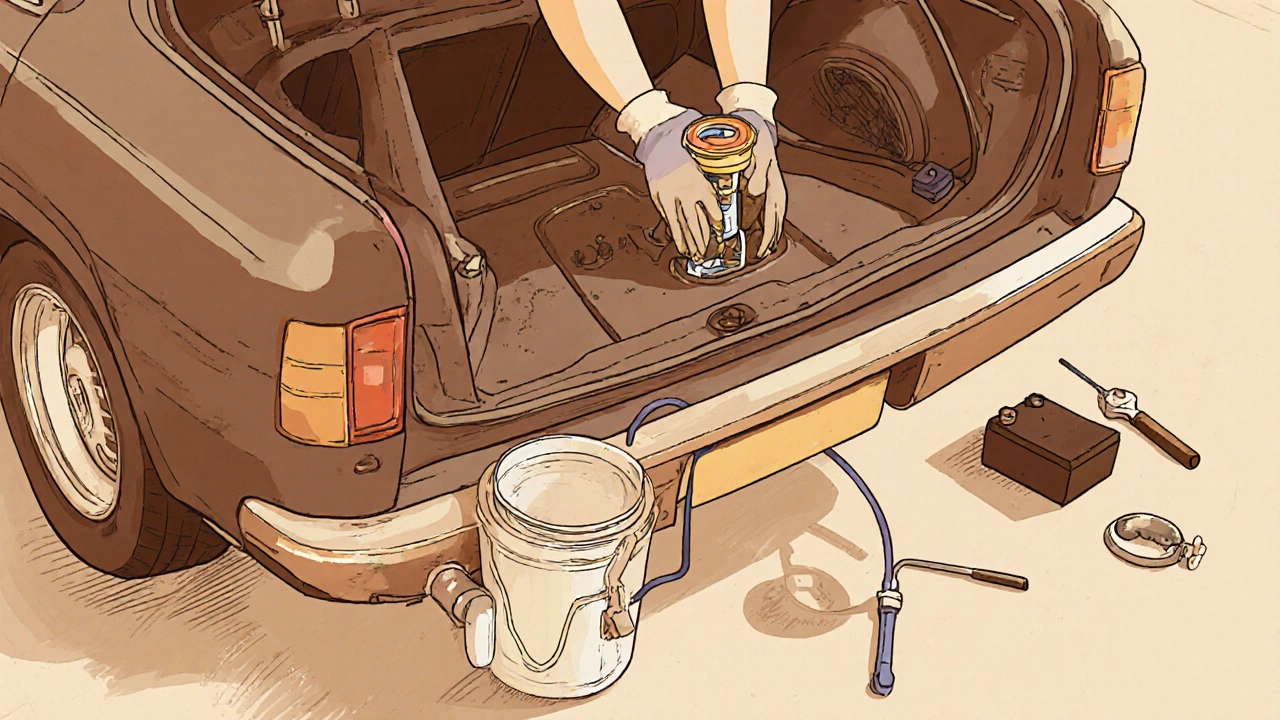

- Remove the rear seat or access panel to reach the pump.

- Unbolt the pump, disconnect the electrical connector and fuel lines (use a catch‑can).

- Install the new pump, replace seals, re‑pressurise the system, and test for leaks.

First‑time DIYers should consult a Haynes or Chilton manual for model‑specific torque specs.

Step‑by‑Step Replacement Guide (Front‑Engine, Mid‑Size Car)

- Safety first: Park on level ground, engage the handbrake, and disconnect the negative battery terminal.

- Locate the fuel‑pump access panel (often under the rear‑seat cushion). Remove the seat cushion using a socket wrench.

- Remove the pressure‑release valve from the fuel line. Turn the key to ‘ON’ for a second to relieve the remaining pressure, then turn it off.

- Unscrew the retaining bolts holding the pump module to the tank. Gently pull the pump assembly out - be careful not to damage the vent hose.

- Detach the electrical connector and fuel‑line fittings. Plug a fuel‑catch can under the lines to collect any spillage.

- Replace the old pump with the new one, ensuring the O‑ring is seated correctly. Re‑install the retaining bolts to the manufacturer’s torque.

- Reconnect the electrical plug, re‑attach the fuel lines, and reinstall the vent hose.

- Re‑install the access panel and rear‑seat cushion.

- Reconnect the battery, turn the key to ‘ON’ for a few seconds to prime the pump, then start the engine. Watch for steady fuel pressure and listen for any abnormal noises.

- Check for leaks around the pump and fuel‑line connections after a short drive.

After a successful replacement, clear any stored error codes with the OBD‑II scanner and take note of the improved idle.

Maintenance Tips to Keep Your Fuel Pump Healthy

- Swap the fuel filter every 30,000km. A clogged filter forces the pump to work harder.

- Buy reputable fuel with a clean‑burn rating. Low‑quality gasoline can leave deposits inside the pump.

- Avoid running the tank below a quarter full; the pump uses the fuel as a coolant and lubricant.

- Keep the fuel pressure regulator in good shape - a failing regulator mimics pump symptoms.

- Periodic checks of the fuel gauge for accuracy can warn you of fuel‑delivery inconsistencies.

Quick Diagnostic Checklist

| Symptom | Likely Cause | Test/Action |

|---|---|---|

| Sputtering at idle | Low fuel pressure | Measure pressure with gauge |

| Whining from tank | Worn pump bearings | Listen for motor noise |

| Engine won’t start after sitting | Seized pump motor | Turn key to ON, listen for pump |

| Fuel smell inside cabin | Leaking pump seal | Inspect pump housing for drips |

| Check‑engine light with P0230‑P0234 | Fuel‑pump performance | Read codes with OBD‑II scanner |

Frequently Asked Questions

What’s the normal fuel‑pressure range for a gasoline engine?

Most modern gasoline engines run between 30 and 55psi. Exact numbers vary by make, so check the service manual for your model.

Can a bad fuel filter mimic a failing pump?

Yes. A clogged filter restricts flow, dropping pressure and causing similar stalling or power‑loss symptoms. Replacing the filter is a cheap first step.

Do I need a special tool to remove the fuel pump?

Most pumps are secured with standard bolts and a retaining ring. A basic socket set, a line‑disconnect tool, and a fuel‑catch container are usually enough.

How often should I replace my fuel pump?

There’s no set interval. Replace it when pressure drops, the motor noises, or you see a leak. Many pumps last 100,000‑150,000km if the fuel is kept clean.

Will a low‑quality fuel damage my pump?

Cheap, sulfur‑rich gasoline can leave deposits that choke the pump’s internal passages. Using reputable fuel and changing the filter regularly reduces the risk.