Suspension-Engine Symptom Checker

Identify Your Symptoms

Select all symptoms you're experiencing to get a preliminary diagnosis

Preliminary Diagnosis

Ever felt a shudder in the engine that seemed linked to a rough ride? It’s not a coincidence - a worn Suspension system the collection of springs, dampers, control arms and bushings that keep your car stable can put extra stress on the engine the power‑producing heart of the vehicle, converting fuel into motion. This article untangles how the two interact, flags the symptoms that point to a suspension‑engine link, and gives you a clear plan to keep both running smoothly.

Key Takeaways

- Bad suspension engine impact often shows up as vibration, reduced power or premature wear on engine components.

- Common culprits are worn shocks/struts, loose control arms, degraded bushings and broken engine mounts.

- Simple visual checks and road‑test cues can reveal if the suspension is the hidden cause.

- Regular alignment, bushing replacement and mount inspection prevent costly engine knock‑on damage.

- When the problem persists, a professional diagnosis that looks at the drivetrain and suspension together is essential.

Why the Suspension Matters to the Engine

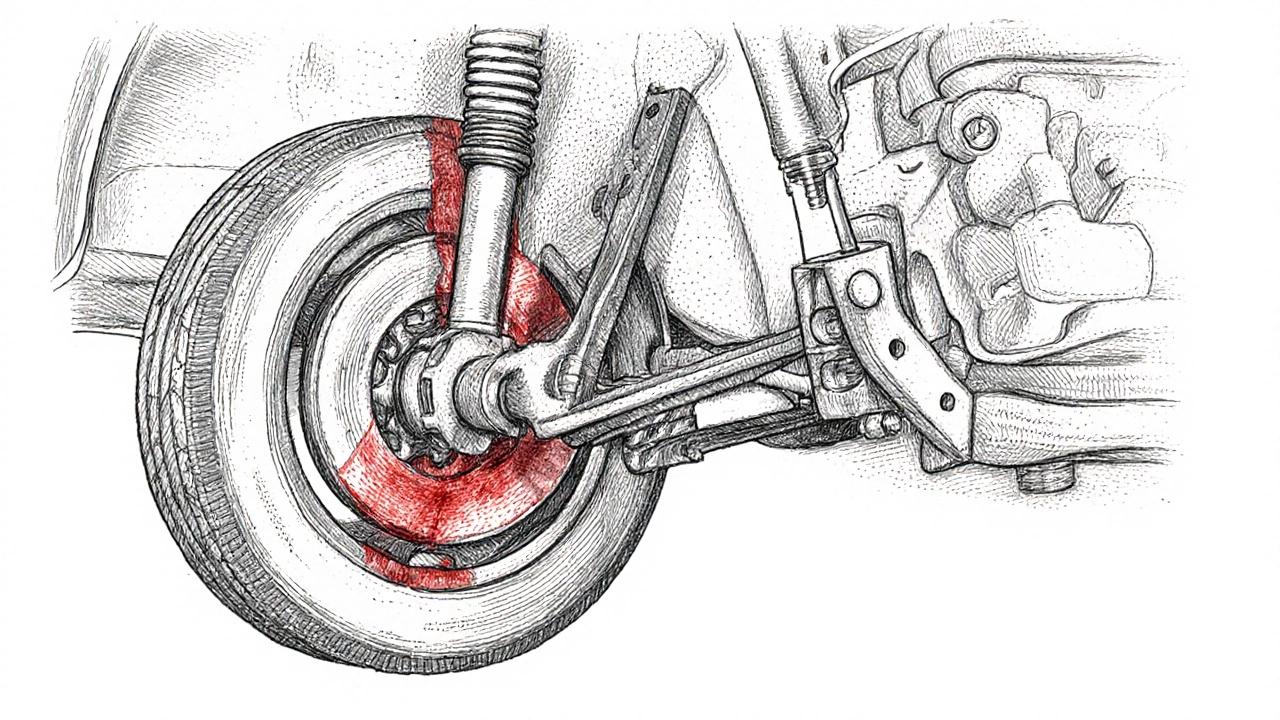

The suspension’s job is to absorb bumps and keep the wheels in contact with the road. When it can’t do that, forces travel up the chassis and hit the engine mounts rubber or hydraulic cushions that isolate the engine from chassis vibration. If the mounts are already soft or cracked, the extra shock can cause the engine to shift, leading to mis‑alignment of the CV joints constant‑velocity joints that transmit power from the transmission to the wheels and even bend the crankshaft.

Think of the car as a chain of parts: wheels → suspension → chassis → engine mounts → engine → drivetrain. A weak link at any point changes how the rest behave. That’s why a bad shock can make the engine feel like it’s “misfiring” even when the spark plugs are fine.

Common Suspension Problems That Stress the Engine

| Suspension Issue | Engine Symptom | Why It Happens |

|---|---|---|

| Worn shocks/struts damper units that control bounce | Excessive vibration at 60‑80km/h | Uncontrolled rear‑end movement transfers load to engine mounts |

| Loose control arms arms that keep wheel alignment | Engine “pulses” during cornering | Wheel mis‑alignment forces the drivetrain to work harder, stressing the crankshaft |

| Degraded bushings rubber inserts that reduce metal‑on‑metal contact | Irregular idle, occasional stalling | d>Vibrations travel through the suspension into the engine bay, disturbing fuel‑pump flow|

| Broken or sagging springs coils that support vehicle weight | Loss of power on inclines | Changed ride height alters the angle of the intake manifold, affecting airflow |

| Failed engine mounts mounts that dampen engine vibration | Clunking noise when accelerating | Mount failure lets suspension forces directly hit the engine block |

How to Spot a Suspension‑Engine Connection

- Listen for new noises. A metallic clunk when you hit a pothole often points to a mount or bushing issue.

- Feel for vibrations. If the vibration changes when you go over bumps, the suspension is likely the source.

- Check ride height. Uneven height suggests a broken spring or shock, which can tilt the engine.

- Do a quick wheel‑turn test. With the car on level ground, push the front wheels left‑right. Excessive play hints at worn control arms or bushings.

- Monitor engine performance. A drop in fuel efficiency or a sudden loss of power after a rough ride is a red flag.

If any of these steps point to a suspension fault, address it before the engine starts to show wear. The cost of a new engine mount is pennies compared with a rebuilt engine.

DIY Inspection Checklist

- Raise the car safely with a jack and support stands.

- Inspect each shock/strut for oil leakage or dented pistons.

- Look at control arms for bent or cracked metal.

- Feel every bushing - any softness or cracking is a sign to replace.

- Check all engine mounts for cracks, separation of rubber, or excessive movement when the engine is revved.

- Measure the distance between the chassis and the tire sidewall; uneven gaps indicate a sagging spring.

Tools needed: jack, stands, flashlight, small pry bar, and a torque wrench for mounting bolts.

When Professional Help Is Needed

If you’ve run the checklist and the engine still feels off, it’s time to bring the car to a qualified mechanic. Ask them to perform a chassis‑dynamics scan - a computer‑aided test that measures how forces travel through the suspension and into the drivetrain. This scan can pinpoint hidden issues such as:

- Subtle mis‑alignment of the drivetrain assembly of transmission, driveshaft and differential caused by a warped subframe.

- Early wear on the fuel pump pump that delivers gasoline from the tank to the engine due to constant vibration.

- Excessive wear on the exhaust system pipes and muffler that expel combustion gases, which can become cracked by chassis flex.

A professional can also verify that the wheel alignment is within OEM specs - typically 0.1° toe and 1.0° camber - because out‑of‑spec alignment adds lateral forces that the engine must counteract.

Preventive Maintenance Routine

Sticking to a regular schedule is the cheapest way to keep suspension and engine health in sync.

- Every 12,000km: Visual inspection of shocks, struts, and mounts.

- Every 24,000km: Replace front bushings if they show any signs of cracking.

- Every 48,000km: Full alignment check and suspension component replacement if wear exceeds 10% of original thickness.

- Every 80,000km: Swap out rear springs and re‑mount engine mounts as a preventive measure.

These intervals match the recommendations from major manufacturers like Volkswagen, Ford and Toyota, and they work equally well for everyday UK drivers dealing with pothole‑laden roads.

Bottom Line

A healthy suspension does more than give you a smooth ride - it protects the engine from unnecessary shock, keeps the drivetrain aligned, and preserves fuel‑pump life. By watching for vibration, listening for clunks, and performing a quick visual check, you can catch problems before they force you into a costly engine repair. Remember, the car is a system; treat the suspension and engine as teammates, not isolated parts.

Frequently Asked Questions

Can a bad shock absorber really damage my engine?

Yes. When a shock can’t control bounce, the rear of the chassis moves excessively. That motion transfers to the engine mounts, causing them to wear faster and allowing the engine to shift, which can stress the crankshaft and CV joints.

My car vibrates at highway speeds but feels fine on city streets. Is the suspension to blame?

Often, yes. High‑speed vibrations are usually amplified by worn bushings or a soft rear bushing. The faster the wheels spin, the more the suspension’s looseness feeds into the chassis, creating a noticeable hum that reaches the engine.

How do I know if my engine mounts need replacement?

Look for a deep clunk when you accelerate or hit a bump, and notice if the engine rocks more than a few centimeters when you rev it in neutral. Visible cracks, rubber separation, or oil seepage are also clear signs.

Is wheel alignment related to engine wear?

Indirectly. Mis‑aligned wheels force the drivetrain to compensate for uneven forces, which can cause additional vibration that travels to the engine mounts. Over time, that extra stress can wear internal engine components.

What’s the cheapest way to prevent suspension‑related engine problems?

Stick to the preventive maintenance schedule: replace worn bushings, check shock oil levels, and keep engine mounts in good condition. A quick visual inspection every 12,000km is often enough to catch issues early.